Our stone mason specialises in crafting both standard and bespoke natural stone products, tailored to meet the unique needs of each project. With a commitment to quality and craftsmanship, we offer a diverse selection of surface finishes that enhance the aesthetic appeal and functionality of our stone products. Whether you are looking for a rustic charm or a sleek modern look, our range of finishes can accommodate various design preferences, making our offerings suitable for both residential and commercial applications.

The finishes available include Stugged, which provides a textured surface ideal for outdoor settings, and Broached, known for its distinctive, rough-hewn appearance. For those seeking a more refined look, our Droved and Punched finishes offer a smooth yet visually interesting surface. The Parallel Punch finish adds a unique pattern, while the Pitched Face finish is perfect for creating a dramatic effect in architectural designs. Each finish is meticulously applied by our skilled artisans, ensuring that every piece not only meets but exceeds industry standards.

Working with stone is a specialist skill which has been mastered over generations by hard working individuals, these skills are reflected in the incredible unique stone architecture across the British Isles. When restoring, extending or building a new development with stone, it's paramount that the stone look and feel is accurately matched. We are proud to offer a curated selection of stone types and finishes to aid in this matching process. Our specialist team of consultants can advise the best suited finish or stone type for your project and can guide you as required to find the perfect stone finish.

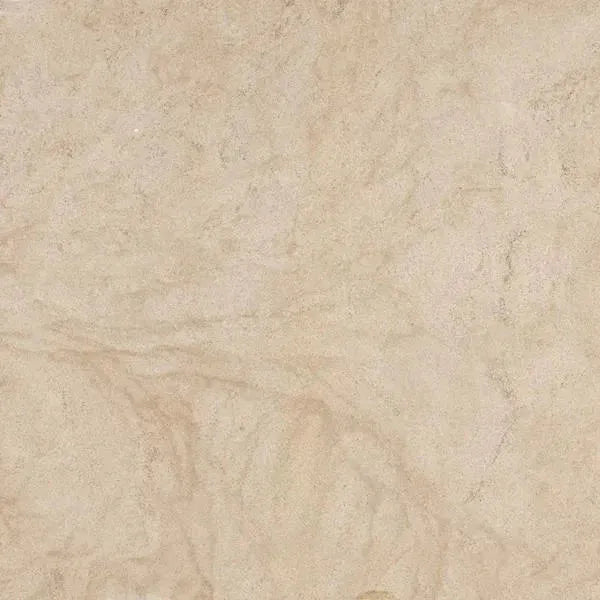

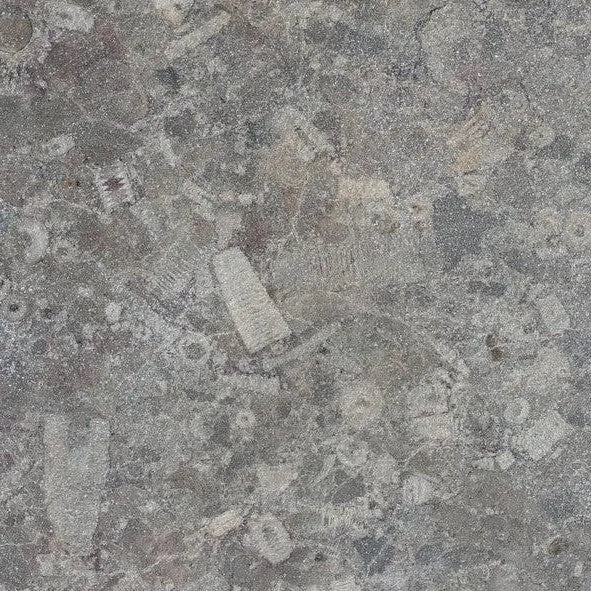

Sparrow Pecked

The Sparrow Peck or Convict Pick Finish is characterised by hand etched pitting of the surface of the stone. This heritage finish is commonly used as cladding and provides an exceptional, traditional depth and feel to a building.

Droving

The Sparrow Peck or Convict Pick Finish is characterised by hand etched pitting of the surface of the stone. This heritage finish is commonly used as cladding and provides an exceptional, traditional depth and feel to a building.

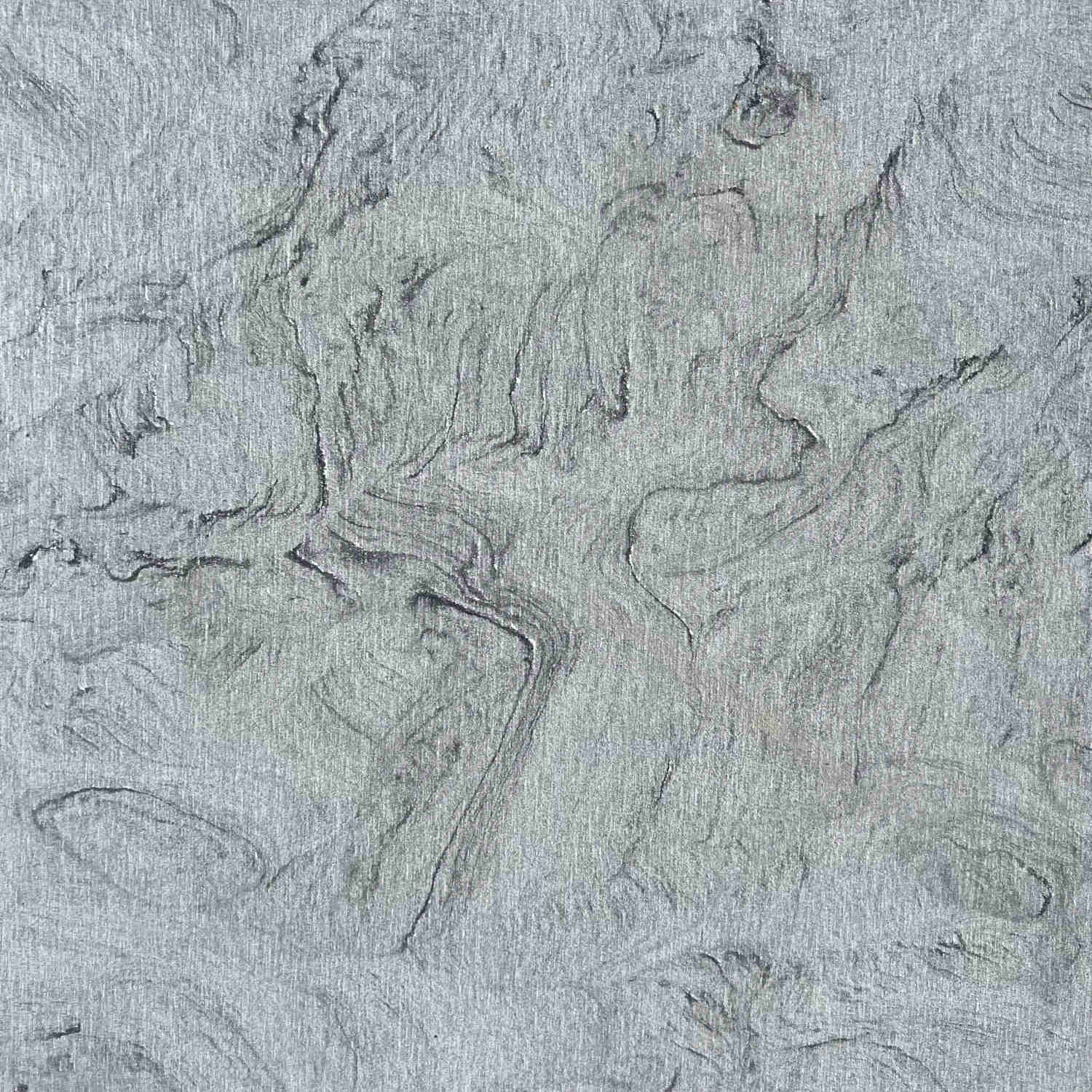

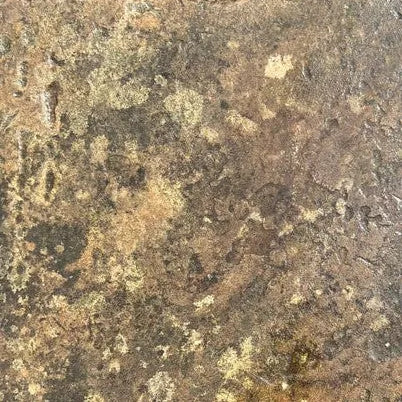

Broaching

Broaching is characterised by parallel lines closely grooved into the face of the stone work, to create a detailed textured affect.

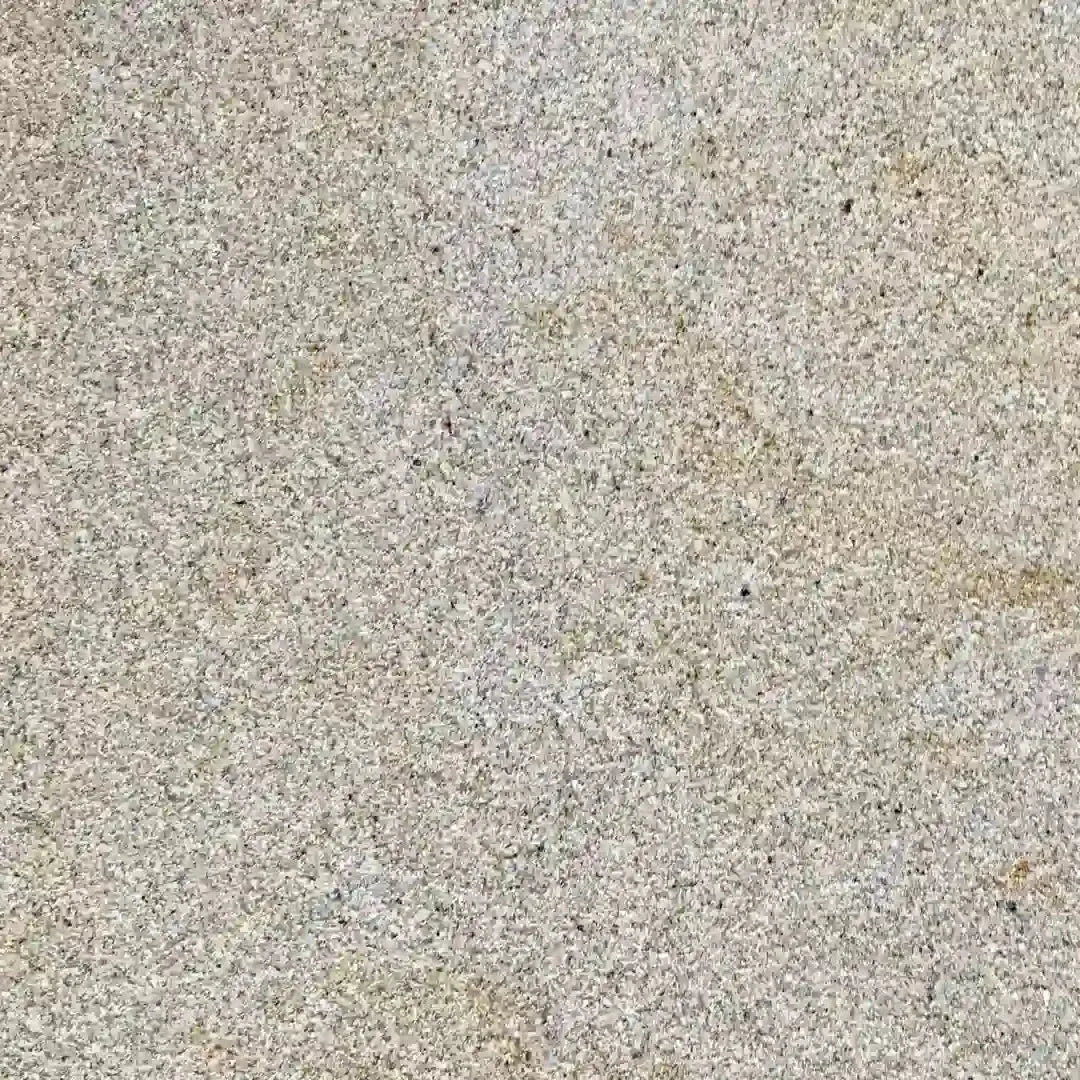

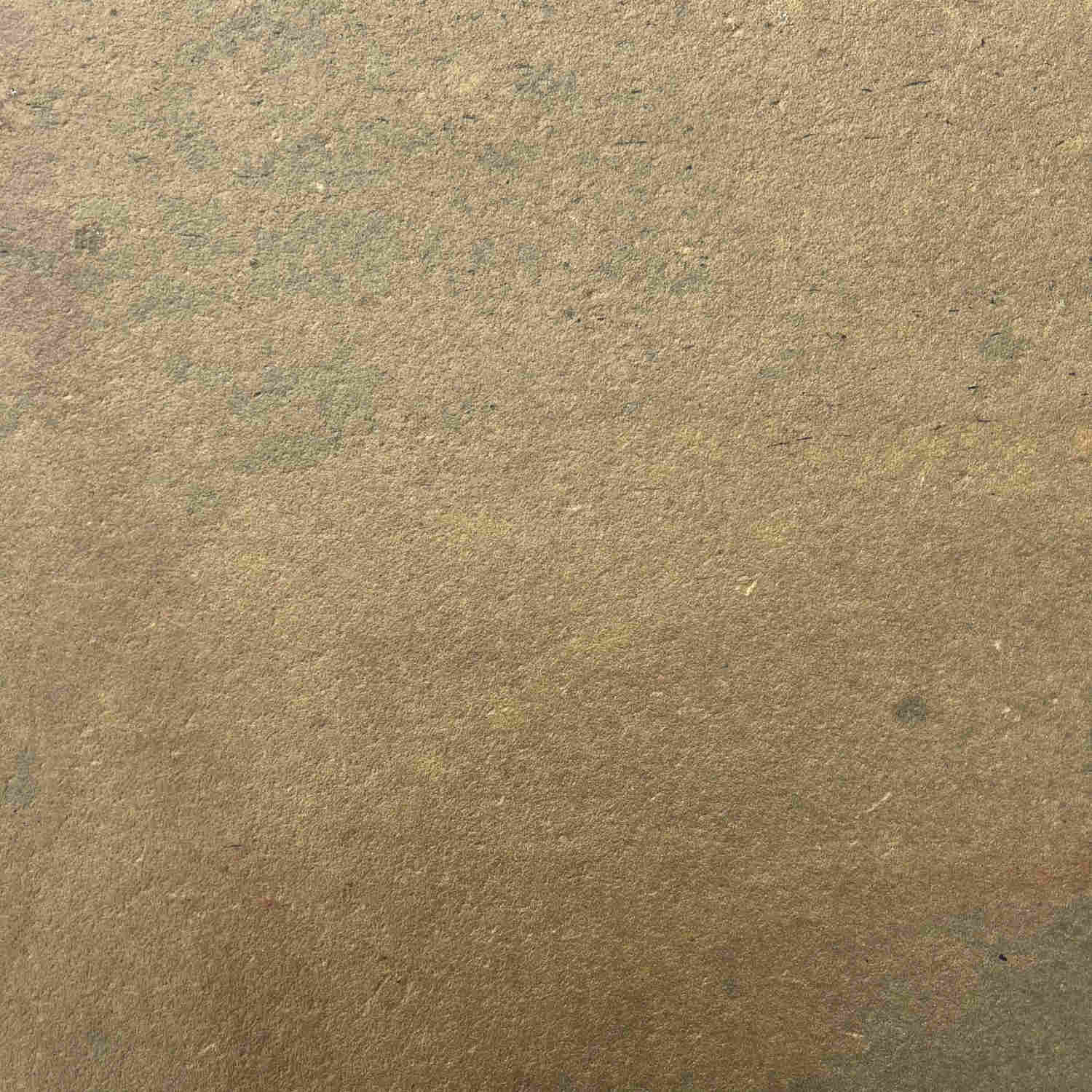

Parallel Punched

Parallel Punch can be found in various areas around the UK made up of different stone types e.g. sandstone, gritstone etc. The parallel punched texture comes from the stone face originally been hand worked in a parallel method to flatten the face.

This stone type is now popular for extensions and garages to match existing buildings.

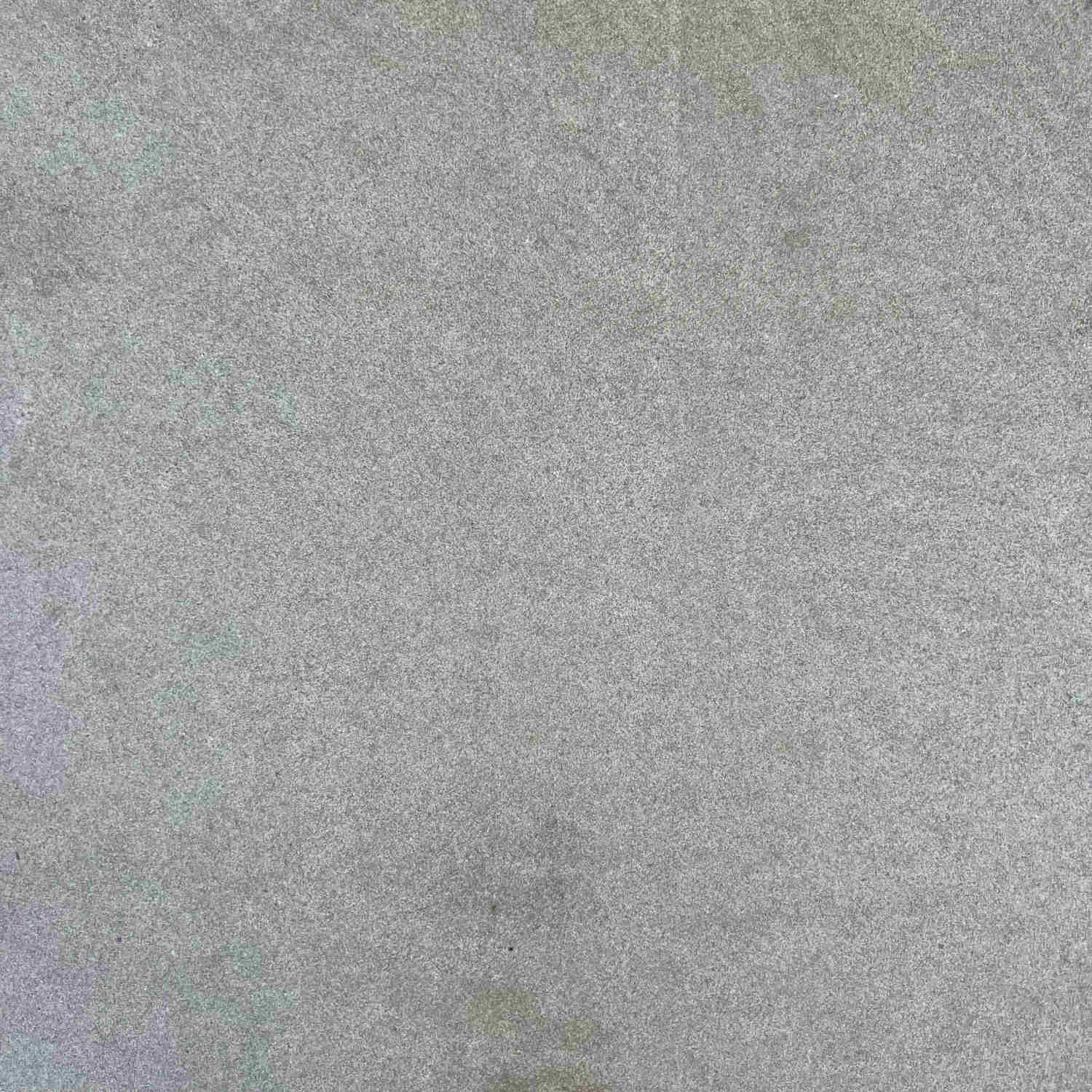

Punched Face

The term Punched Finish refers to the finish on the face of the stone. Theses marks can be hand tooled or machine produced, both processes create hollows and ridges on the surface of the stone. This technique was traditionally applied to simply flatten the face of the stone.

Punched stone is mainly used as walling stone but this finish can also be applied to masonry items such as quoins, heads & cills, gateposts and coping stones.

Herringbone Punched

Herringbone punch face stone is characterised by punch marks running in a herringbone pattern on the face of the stone block, to create a detailed textured affect. A decorative take on the standard punched face finish.

Scutch Punched

Scutch punch face stone is characterised by small punched marks or scutches running in a random pattern on the stone face, to create a detailed textured affect.

Tumbled

The tumbling process imparts a gentle, time-worn texture, evoking a sense of history while ensuring the structural integrity of the stone. This type of stone is carefully crafted to maintain a uniform depth, facilitating easier installation whilst creating a more worn and aged appearance.

Pitched Face

The key feature of pitched faced walling is the raised centre to give depth to a completed wall. The high technical performance characteristics of the material ensure its durability, while the versatile nature means it looks and performs well in any environment.

Horizontal Stugged

The surface of the stone face is gently stugged or punched by hand in a controlled manner in a horizontal direction. The finish is to create depth and character to the stone face.

Diagonal Stugged

The surface of the stone face is gently stugged or punched by hand in a controlled manner in a diagonal direction. The finish is to create depth and character to the stone face.

Weathered

Natural building & walling when freshly quarried can be bright in colour, to help match in with existing surrounds, facing stone can be weathered with natural solutions. To give an aged / darken look to the stone face. This technique is very common in restoration projects and matching stone house extensions.

Bespoke Masonry

Rely on our collective expertise and years of experience to shape, finish and create bespoke natural building stone marvels to your own requirements from a wide range of curated stone types below.

Benefits of using our Bespoke Masonry Service

Choice Your Stone

Britannia Stone have carefully curated the finest selection of British Natural Stones, all in one place. Each stone type is available in building and masonry product options, for your selection.

Made to Order

We offer a completely bespoke and made to order service, our team of highly skilled stone masons are on hand to bring your vision to life.

Personalised Experience

With a customer centric approach, Britannia Stone provide a tailored and personalised experience...

Bespoke Stone Masonry FAQ

What is the lead time on orders?

On average we advise 3-5 weeks on all bespoke masonry commissions.

Though, this can vary depending on the complexity of the order, size of order, material availability and current work load.

For off the shelf stone products, we advise 1-2 week lead time.

Can we choice our own stone?

Britannia Stone are proud to offer a board range of different stone types from across the British Isles that have been carefully curated over decades to offer the broadest selection of stone colours and textures all in one place.

This curated range of stone types are available to our customers for bespoke masonry commissions.

Can you CAD model our design?

Yes, we can model design concepts on CAD.

Do you deliver?

Yes. We deliver to all postcodes in the UK. For standard deliveries there needs to be enough room for an 26 ton rigid wagon to manoeuvre and for the driver to pull the pallet on to the kerb from the road.

Standard delivery is by manual pump truck and tail-lift. Delivery can only be made to a flat, solid surface. Deliveries cannot be made on grass or gravel.

If you require a crane grab or are unsure whether your address is suitable please contact us at 0114 2061113 or info@britanniastone.co.uk and we will advise you.